A large metal sheet of thickness l is placed between and parallel to the plates of the parallel plate capacitor of the figure.

A large metal sheet of thickness l displaced between.

It does not touch the plates and extends beyond their edges.

The starting material for sheet and plate production is slabs metal blocks.

Item 168753 model 11786.

Thickness that is more than 6mm or 0 25 inches is called plates.

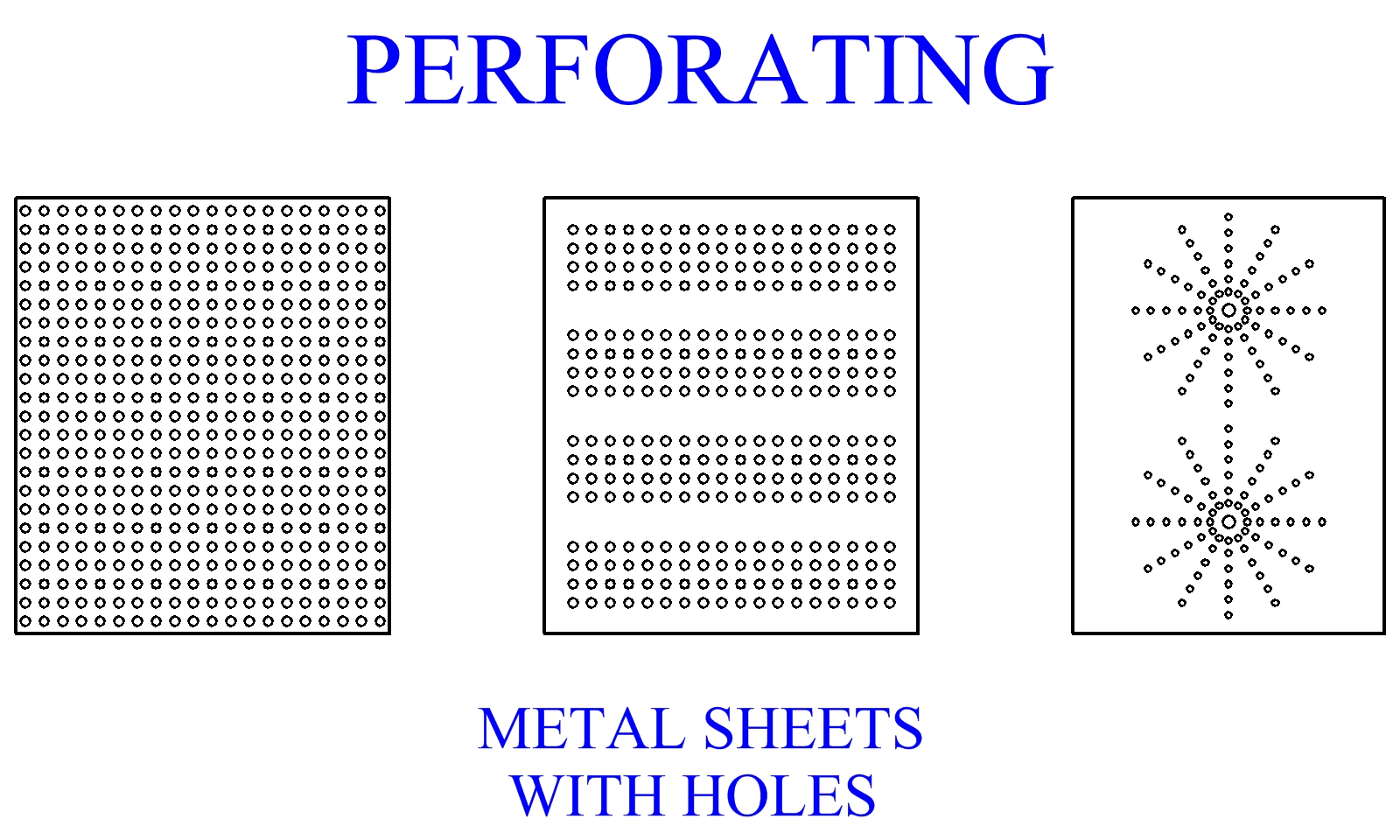

The sheet features a union jack style perforated design.

Sheets are used in a variety of industries for repairs and maintenance and are typically less than 3 16 thick.

The md building products 36 in.

A large copper sheet of thickness l is inserted between the plates of a parallel plate capacitor.

Hillman 12 in x 24 in cold rolled steel expanded sheet metal.

Sheet is available in hot cold rolled steel galvanized aluminum stainless steel brass and copper.

Mill aluminum union jack style perforated sheet metal offers a decorative way to complete your hvac door window hobby and cabinet projects.

If l 0 55 d what factor does the capacitance change when the sheet is inserted.

It can be purchased online and at any metal supermarkets location.

X 36 the md building products 36 in.

The distance btw each plate and the sheet is dprime l 2 where dprime is the distance.

Figure 4 4 shows a large temperature difference between the top and bottom surfaces of the sheet.

Sheet is measured in gauges.

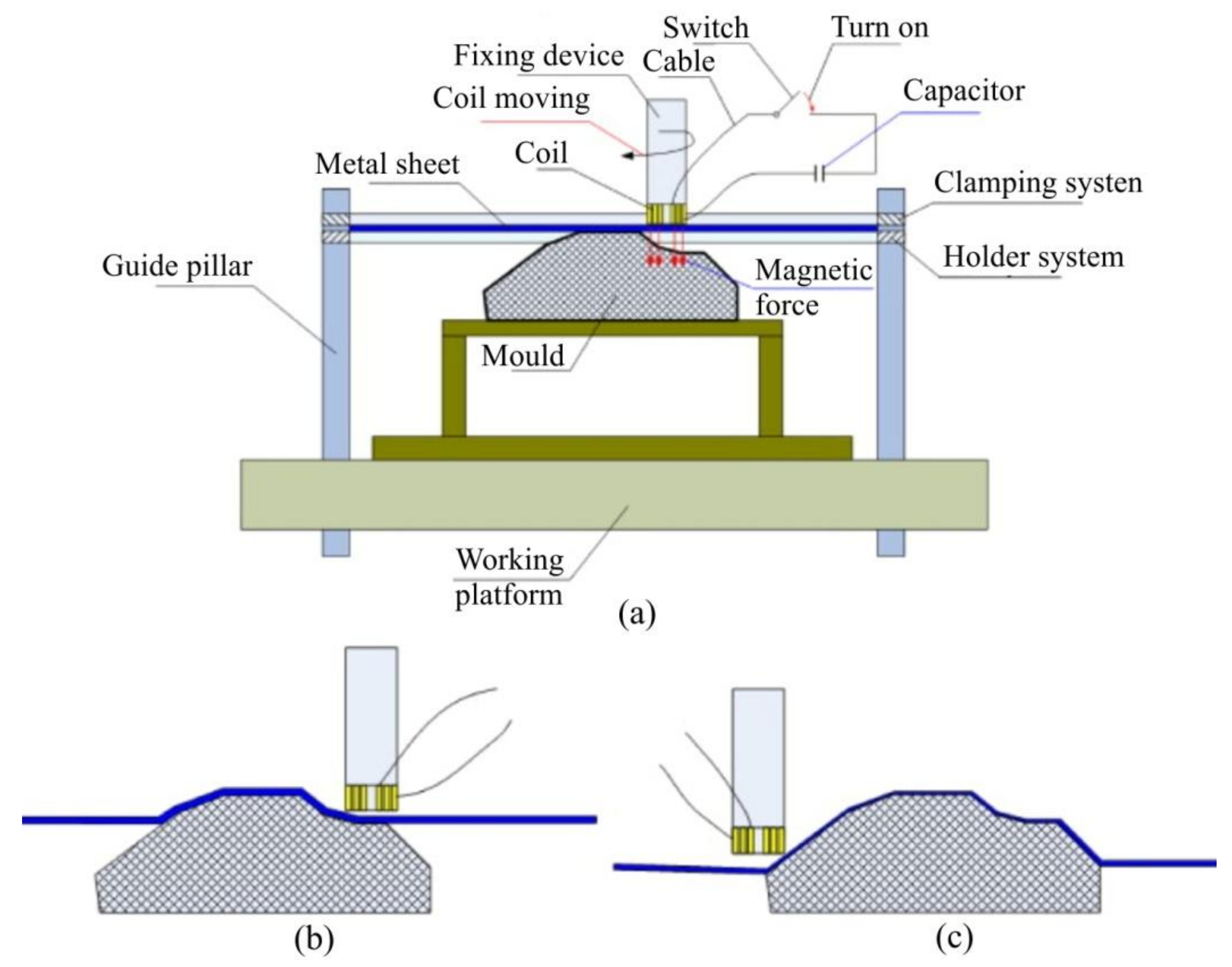

It can also be seen that the counter bending of about 1 5 occurs at time 1 s.

Plain metal sheets of architectural quality vary in thickness between 025 60 mm and 124 3 mm.

Nevertheless in some situations sheet metal s thickness can vary significantly which is then called foil or leaf.

What is now the net capacitance in terms of a d and l.

It is easy to work with and very attractive in the home.

Larger thicknesses are produced by hot rolling working the metal in red hot condition and smaller thicknesses are produced by cold rolling.

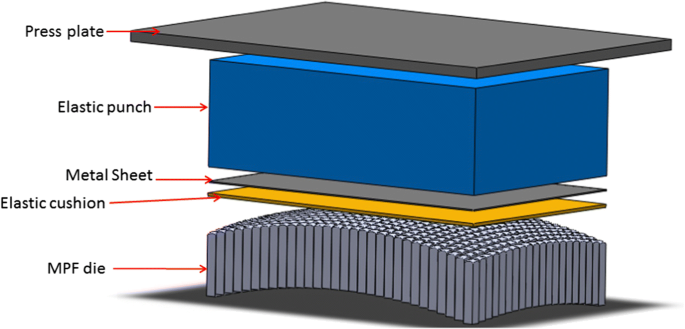

The large gradient along the thickness direction generates the plastic strains which produces the bending of the metal sheet.

The customary range gauge of a metal sheet is from a scale of 35 going down to 6.

These materials can be usually seen in construction works and are used for.

These are driven between rolls with increasingly closer distance between the rolls until the required thickness is achieved.